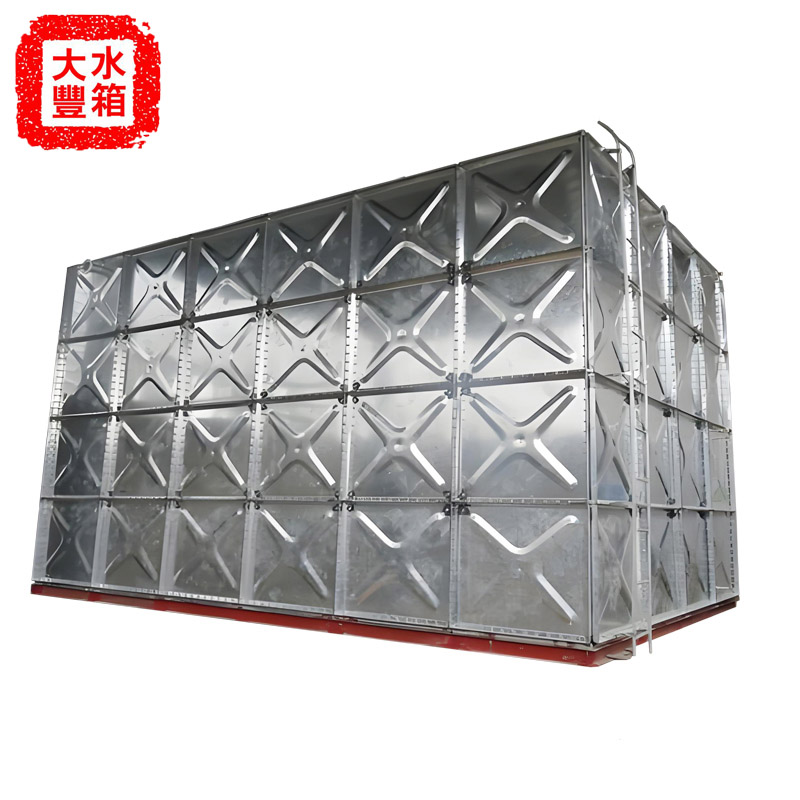

Galvanized civil air defense water tank

ShanDezhou Dafeng Glass Products Co., Ltd. has a high-quality R&D team and advanced production equipment, which can customize various specifications of water tank products according to customer needs. The galvanized water tank produced by the company adopts advanced hot-dip galvanizing technology, which forms a dense zinc layer on the surface of the water tank and has good corrosion resistance.

Precautions for maintenance of galvanized steel plate water tank:

Anti corrosion maintenance should be carried out regularly. When white rust (alkaline zinc carbonate) appears on the galvanized layer, use a hard bristled brush to remove it and apply epoxy resin paint. If red rust is found, it needs to be

polished to a metallic luster before spraying cold galvanized coating. Internally, a comprehensive anti-corrosion treatment is carried out every three years. However, a certain water treatment station neglected internal maintenance and after five years of use, the casing showed extensive rusting. After welding repair, anti-corrosion treatment must be carried out again. If the repair area exceeds 10%, it is recommended to replace it as a whole.

Security measures cannot be ignored. Water tanks exceeding 2 meters in height should be equipped with anti climbing

guardrails, with a grounding resistance not exceeding 4 ohms. Independent lightning rods should be installed in areas

with frequent thunderstorms, with a horizontal distance of at least 3 meters from the water tank. The load calculation

should take into account the maximum amount of snow in the local area, as there was an accident in Northeast China

where snow crushed the roof. Attention should be paid to wastewater treatment in terms of environmental protection.

Zinc containing wastewater generated during cleaning should be collected and handed over to professional institutions

for treatment. Direct discharge into the sewer is prohibited. Dust protection measures should be taken during the

dismantling of waste water tanks, and water mist dust reduction devices should be used for cutting operations.

Special environments require targeted treatment. Sunshades should be installed in high-temperature areas (above 40 ℃)

to prevent deformation caused by thermal expansion and contraction of steel plates. The integrity of the galvanized layer

should be checked monthly around the chemical industrial park. The water tank near a certain electroplating plant was

scrapped after two years due to acid mist corrosion. Mobile water tanks should focus on reinforcing the bottom support

frame and using rubber pads to cushion and shock during transportation. There are methods to deal with common

problems. If a leak is found, first turn off the water source. The small hole can be temporarily treated with underwater

repair agent. If the tear exceeds the size of the nail cover, the steel plate must be replaced. When the water level gauge

fails, manually measure it by tying the ruler with a bamboo pole. The odor issue may be due to the aging of the sealant,

and it is necessary to open the cover for ventilation and replace the sealing material.