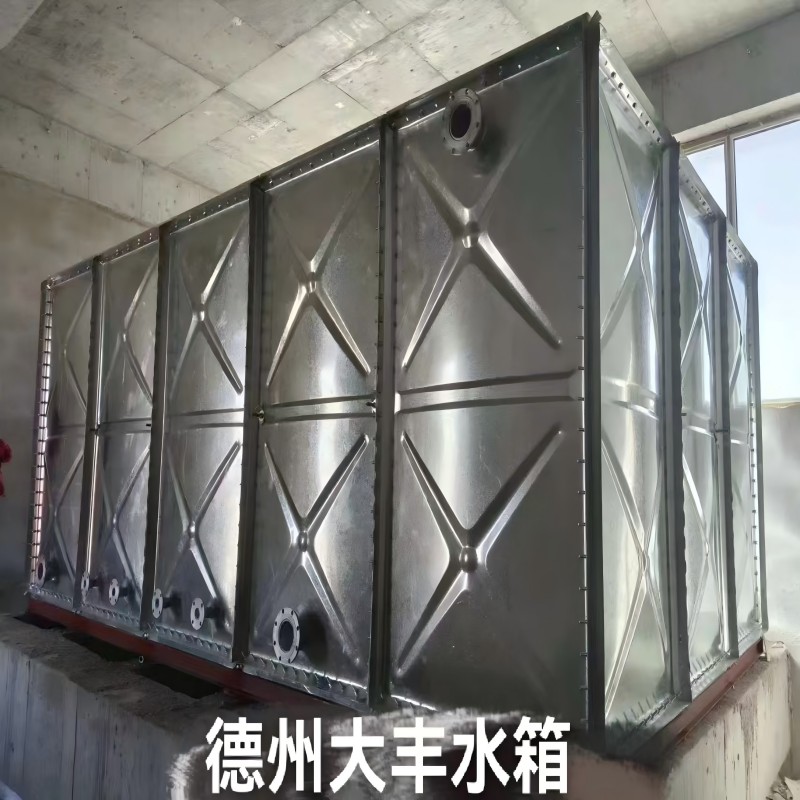

Bolted Stainless Steel Water Tank

Made of high-quality stainless steel materials, these water tanks have outstanding corrosion resistance. They can withstand various chemical substances and environmental factors, ensuring long-term and reliable use without the risk of rust and scaling. This is especially important for storing drinking water and other liquids that require high purity. The screw-connected structure endows the water tank with excellent mechanical strength. It can withstand high pressure and heavy loads, maintaining stable performance even in harsh environments. The stainless steel material also has good impact resistance, reducing the risk of damage caused by external forces. Stainless steel is a non-toxic and odorless material, which is in full compliance with food hygiene standards. It will not contaminate the stored water or other liquids, ensuring the safety and health of the liquid. This makes stainless steel screw-connected water tanks an ideal choice for applications such as drinking water storage, food processing, and pharmaceutical production. Thanks to the screw-connected design, the installation process of these water tanks is relatively simple and convenient. It does not require complex construction techniques and can be quickly assembled on-site. In addition, the smooth surface of stainless steel makes cleaning and maintenance easy. Regular cleaning can be carried out with simple tools and detergents to keep the water tank in good condition.

In-depth Introduction to Stainless Steel Screw-connected Water Tanks

Stainless steel screw-connected water tanks have become an increasingly popular choice in the market for water storage solutions. Their unique design and high-quality materials make them suitable for a wide range of applications, from residential settings to large-scale industrial and commercial projects. In this article, we will delve into the various aspects of these water tanks, including their construction, features, advantages, and applications.The primary material used in the construction of stainless steel screw-connected water tanks is, of course, stainless steel. Different grades of stainless steel are available, with the most commonly used ones being 304 and 316. Grade 304 stainless steel is widely used due to its excellent corrosion resistance in most normal environments. It contains a sufficient amount of chromium (around 18%) and nickel (around 8%), which form a passive oxide layer on the surface, protecting the metal from rust and corrosion.

The distinctive feature of these water tanks is their screw-connected design. The tank is composed of prefabricated stainless steel panels. These panels are precision-cut and formed into the required shape, usually rectangular or cylindrical, depending on the specific requirements of the application.The edges of the panels are designed with grooves or flanges that allow for a secure connection. High-strength screws are then used to fasten the panels together. This screw-connected structure provides several benefits. Firstly, it allows for easy transportation of the tank components to the installation site. Since the panels are relatively lightweight and compact compared to a fully assembled tank, they can be easily moved and maneuvered, even in areas with limited access.Secondly, the screw-connected design enables quick and straightforward on-site assembly. With the help of basic tools, the panels can be accurately aligned and screwed together, reducing the installation time significantly compared to traditional welded tanks. This is especially advantageous for projects with tight deadlines or in situations where minimizing disruption is crucial.