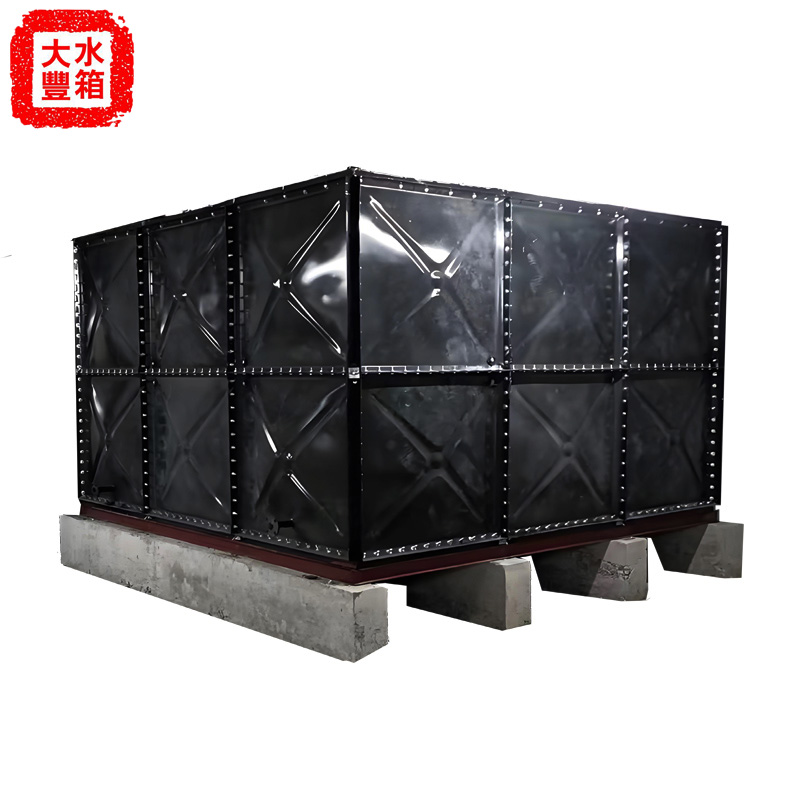

Square Enamel Water Tank

Enamel water tank is a water storage equipment assembled by high-temperature sintering of high-strength enamel steel plates. Our main business in Dafeng is square water tanks, with various specifications and complete types that can be customized according to needs. We have accumulated decades of successful experience in technical production processes, and provide excellent water tank product quality, thoughtful and meticulous sales, and attentive after-sales service to customers.

Enamel steel plate water tanks have a wide range of applications, not only suitable for new construction projects, but also

providing convenient conditions for the replacement of water tanks in old buildings. The water tank can store both cold and hot water, and is resistant to acid, alkali, seepage, leakage, deformation, and corrosion.

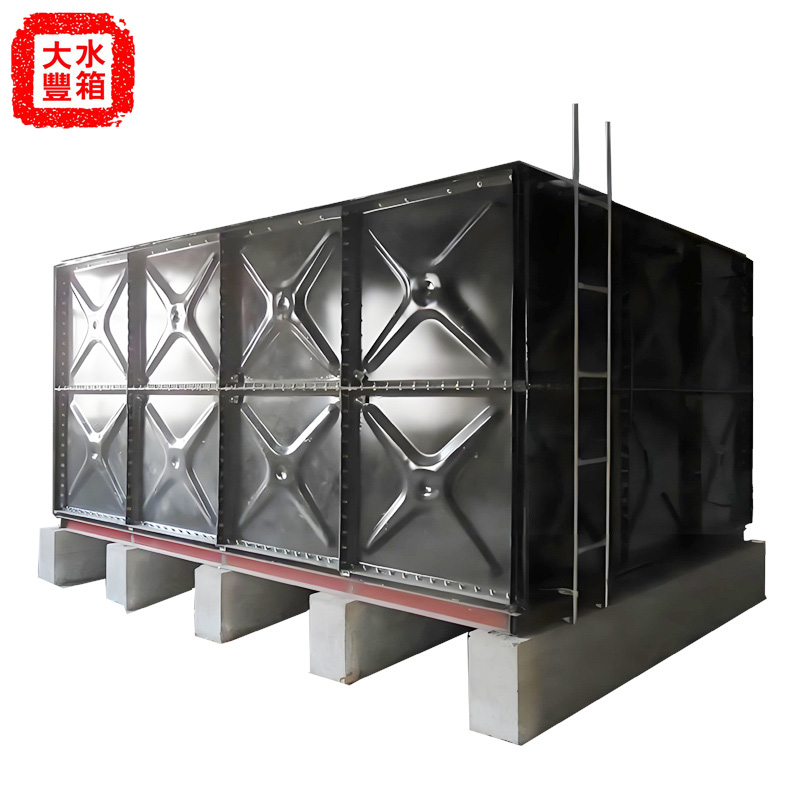

Installation process of enamel steel plate water tank:

1. Basic installation - If it is a concrete foundation, ensure that the foundation surface is flat, dry, and free of cracks. Based

on the size of the water tank, lay out and locate the installation position of the water tank. -If required, rubber shock-

absorbing pads should be laid on the foundation, and the specifications and spacing of the shock-absorbing pads should

be in accordance with the design requirements. Generally, a shock-absorbing pad can be laid every 1-2 meters.

2. Water tank assembly - Starting from the bottom of the water tank, lay the bottom plate on the foundation according to the predetermined splicing method, and use bolts to connect adjacent bottom plate plates. The bolts should be tightened to ensure a tight connection between the bottom plates. The sealing strip should be installed correctly at the splicing point to prevent water leakage. -Install the side panels, erect them one by one, and connect them to the bottom plate. When connecting the side panels, attention should be paid to their verticality, which can be corrected using a plumb line or a spirit level. For each side panel installed, corresponding reinforcement bars are installed, and the reinforcement bars are connected to the side panels by bolts or welding (according to design requirements) to enhance the structural strength of the water tank. -Install the top plate, and after the water tank side plate is installed to a certain height, start installing the top plate. The installation method of the top plate is similar to that of the side plate, and it is necessary to ensure that the connection and sealing between the top plate and the side plate are good. -During the assembly process, all bolted connections should be tightened according to the specified torque values, and the tightening of bolts should be regularly checked to prevent loosening.