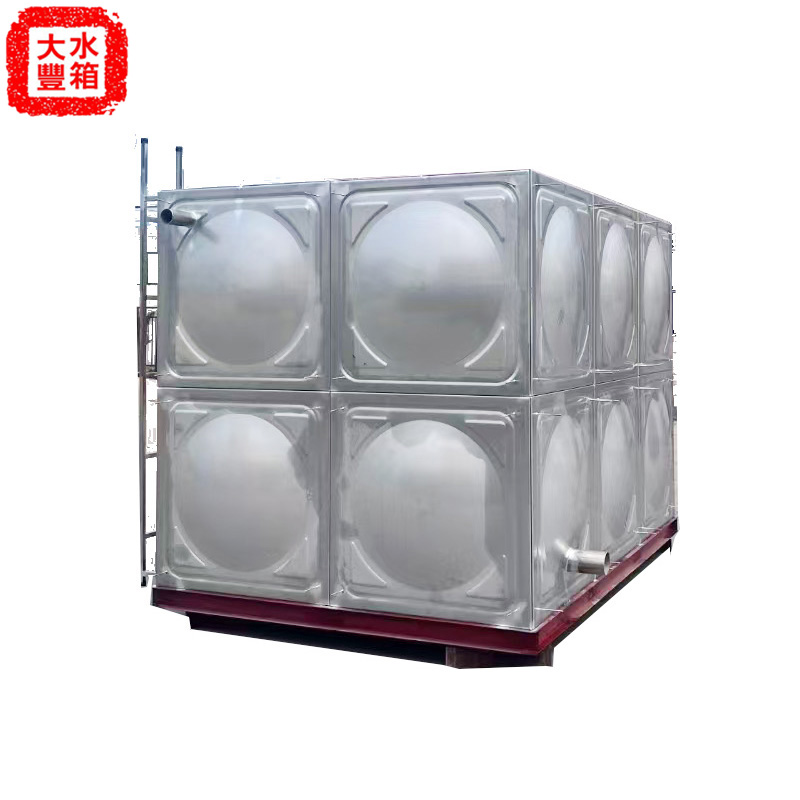

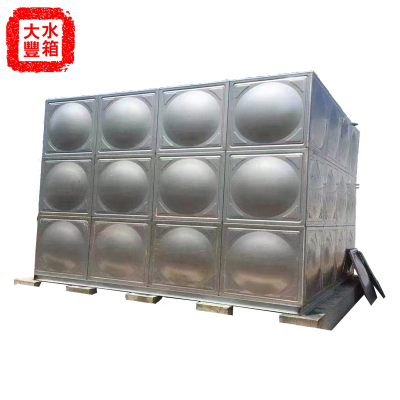

Assembled Stainless Steel Water Tank

Dezhou Dafeng Glass Products Co., Ltd. is a professional manufacturer of stainless steel water tanks. Our company mainly deals with square water tanks made of high-quality stainless steel materials, with various specifications and complete types that can be customized according to needs. We have accumulated decades of successful experience in technical production processes and provide customers with excellent water tank product quality, thoughtful and meticulous sales, and attentive after-sales service. Welcome to inquire and purchase!

Product Details of Assembled Stainless Steel Water Tank

Structural Design and Components

Prefabricated stainless-steel water tanks are composed of multiple pre-cut and pre-formed stainless-steel panels. These panels are typically made of high-quality stainless steel grades, such as 304 or 316, which offer excellent corrosion resistance. The panels are designed with flanges and grooves that allow for precise alignment and connection during assembly. The tank usually consists of side panels, bottom panels, and a top cover. The side panels are often reinforced with internal or external stiffeners to enhance the tank's structural strength and ability to withstand water pressure.

Material Quality and Properties

The stainless-steel material used has several desirable properties. It is highly resistant to rust and corrosion, which makes it suitable for storing various types of water, including potable water, industrial process water, and wastewater. The smooth surface of the stainless steel inhibits the growth of bacteria and biofilms, helping to maintain water quality. Additionally, stainless steel has a good strength-to-weight ratio, allowing for the construction of relatively lightweight yet strong tanks. The material is also non-toxic and does not leach harmful substances into the stored water.

Residential and commercial buildings: Used to store domestic water, drinking water, hot water, etc., typically installed on rooftops or in basements.

Industrial applications: Employed for cooling water, process water, fire water, etc., especially in the food processing and chemical industries.

Agricultural irrigation: Used for storing irrigation or agricultural water to ensure a consistent water supply for irrigation systems.