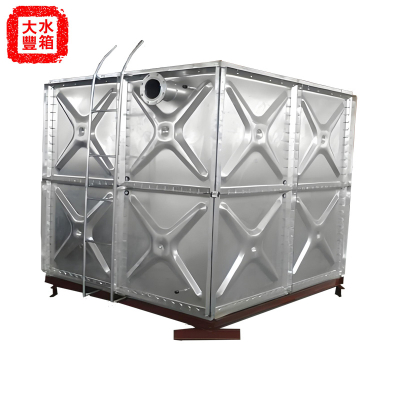

Stainless Steel Water Tank

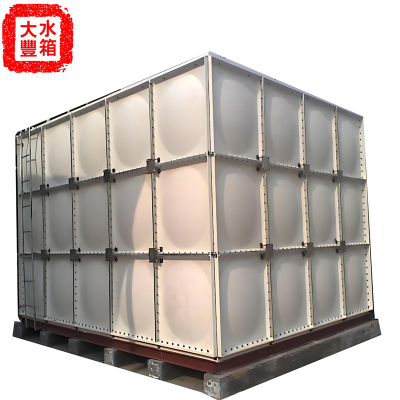

The advantages of FRP water tanks are as follows. Firstly, it has excellent corrosion resistance, which can withstand the erosion of various chemical substances and is suitable for storing different types of liquids. Secondly, its light weight makes it convenient for transportation and installation, reducing labor and equipment costs. Moreover, FRP water tanks have good sealing performance, effectively preventing leakage. They also possess high strength and durability, with a long service life. In addition, they are easy to clean and maintain, saving a lot of time and effort. Overall, FRP water tanks are widely favored in many fields due to their multiple advantages.

Material:

SUS304 is commonly used, with good corrosion resistance, high temperature resistance and hygienic properties, suitable for general domestic water and drinking water storage.

SUS316L has stronger corrosion resistance, especially for areas with poor water quality and high chloride ion content.

SUS201 has a relatively low cost but weaker corrosion resistance, often used for fire water tanks and general solvent storage.

Assemble the pressed stainless steel panels. Weld the panels together using advanced welding techniques. Professional welders are required to ensure the quality of the welding seams. The welding seams should be strong, leak - proof, and aesthetically pleasing. After welding, inspect the welding seams for any defects, such as cracks or porosity.

Surface Treatment

After welding, carry out surface treatment on the welded water tank. This may include polishing to make the surface smoother and more attractive, as well as passivation to enhance the corrosion resistance of the stainless steel. The surface treatment helps to improve the overall quality and appearance of the water tank.

Assembly and Installation

Install accessories such as inlet and outlet pipes, manholes, and overflow pipes on the water tank. Conduct a comprehensive inspection of the assembled water tank to ensure that all components are properly installed and the water tank is in good working condition. Then, transport the water tank to the installation site for final installation.