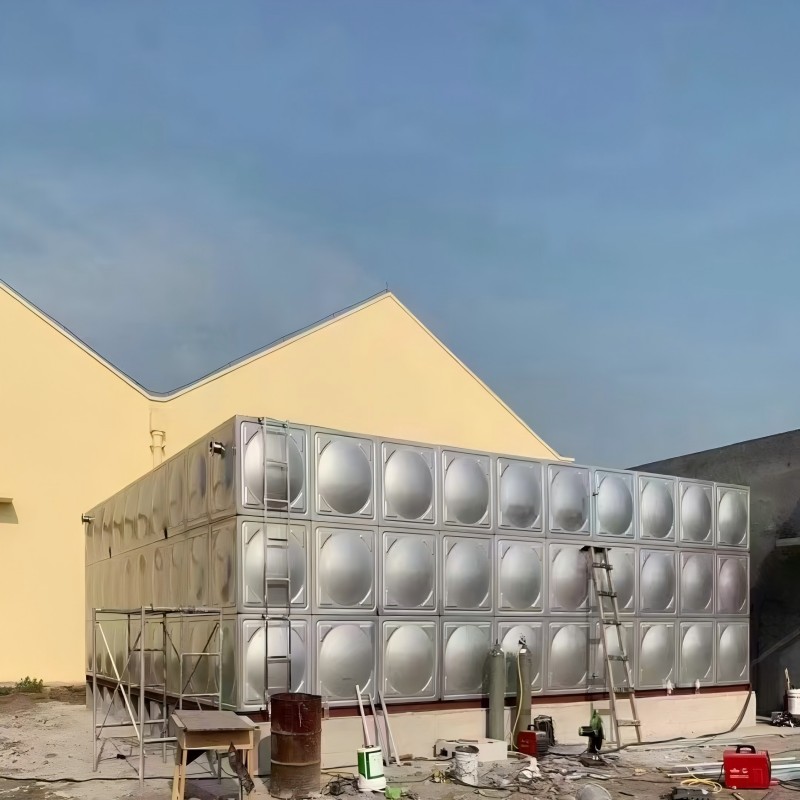

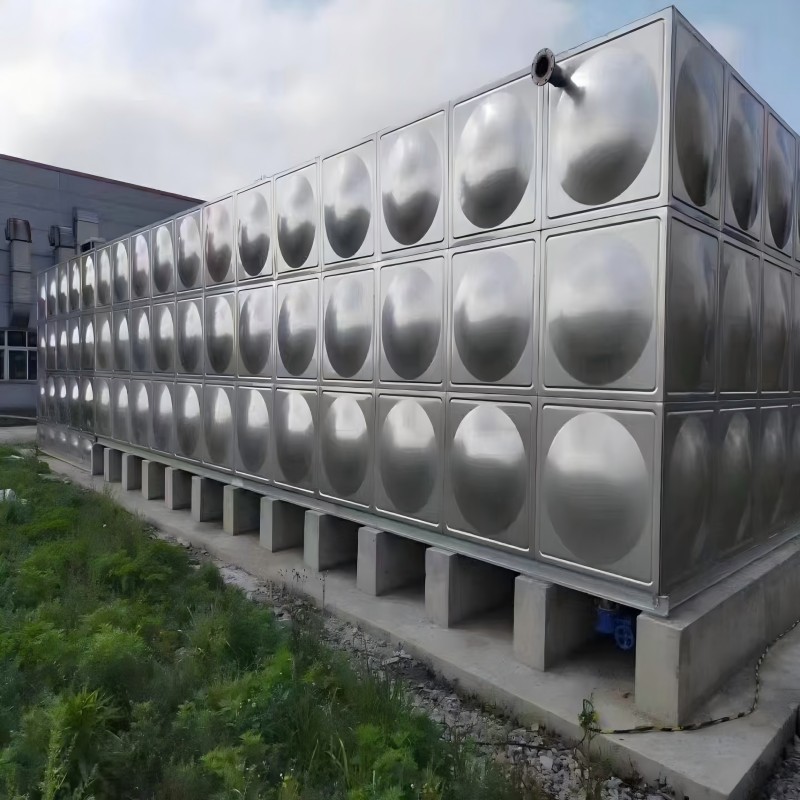

Weld 316 Stainless Steel Water Tank

1. Exceptional Corrosion Resistance

316 stainless steel contains molybdenum, which significantly enhances its resistance to corrosion compared to other stainless steel grades. It can withstand exposure to a wide range of corrosive substances, including chlorides and acids. This makes it highly suitable for storing water in various environments, such as coastal areas with high salt content in the air or industrial settings where the water may have chemical impurities. The tank's surface remains intact and free from rust or pitting, ensuring a long service life and maintaining the integrity of the water storage system.

2. High Temperature Tolerance

This type of stainless steel has good high-temperature resistance. It can endure elevated temperatures without losing its mechanical properties or deforming. This characteristic is beneficial when the stored water needs to be heated or in applications where the tank is exposed to heat sources. For example, in some industrial processes or hot water supply systems, the 316 stainless steel tank can reliably hold and transport hot water without the risk of structural damage, providing a safe and durable solution for temperature - related water storage needs.

Product Details of Weld The 316 Water Tank

Material Composition and Properties

316 stainless steel is an alloy that primarily consists of iron, chromium, nickel, and molybdenum. The chromium content (around 16 - 18%) forms a passive oxide layer on the surface, providing basic corrosion resistance. The addition of nickel (about 10 - 14%) enhances the ductility and toughness of the material. The presence of molybdenum (2 - 3%) is crucial as it significantly improves the resistance to pitting and crevice corrosion, especially in chloride-rich environments. This alloy combination gives 316 stainless steel excellent mechanical properties, including high tensile strength and good fatigue resistance, making it suitable for withstanding the pressure and stress of water storage.

Surface Finish and Hygiene

The surface of 316 stainless steel tanks is usually smooth and can have different finishes. A polished finish not only gives an aesthetic appearance but also helps in reducing the adhesion of dirt and bacteria. The non-porous nature of the stainless steel surface prevents the accumulation of contaminants and makes it easy to clean. This hygienic property is vital for applications where water quality is critical, such as in drinking water supply and food processing industries. The tanks can be cleaned using mild detergents and sanitizing agents without the risk of damaging the material.