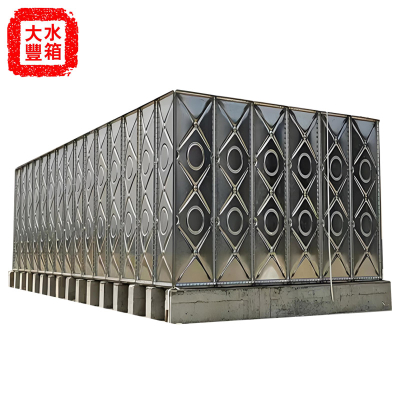

Welded Type Stainless Steel Water Tank

The product advantages of stainless - steel welded water tanks are as follows. Firstly, stainless steel has outstanding corrosion resistance, ensuring the tank's long - term durability and hygienic safety for stored water. Secondly, the welded structure makes the tank highly leak - proof and able to withstand certain pressure. It is also easy to clean and maintain, reducing operational costs. Moreover, stainless - steel welded water tanks have a beautiful and smooth appearance, suitable for various installation environments. They can be customized in different sizes and shapes to meet diverse water storage needs precisely, providing reliable and efficient water storage solutions.

MaterialOur stainless steel welding water tank is made of high-quality stainless steel. The stainless steel material has excellent corrosion resistance, ensuring the durability and long service life of the tank. It can withstand various corrosive substances and environmental conditions, making it suitable for a wide range of applications.

Stainless Steel Welded Water Tank Product Details

I. Introduction

In the realm of water storage solutions, stainless steel welded water tanks have emerged as a top choice for a multitude of applications. Their remarkable combination of durability, hygienic properties, and versatility has made them indispensable in various industries, from residential complexes to commercial establishments and industrial facilities. This product detail aims to provide a comprehensive overview of what makes these tanks stand out.

Material Excellence1. Premium Stainless Steel Grade

- Our stainless steel welded water tanks are crafted from high-quality stainless steel grades, typically 304 or 316. Grade 304 stainless steel offers excellent corrosion resistance in most common environments, making it suitable for a wide range of water storage applications. It contains chromium and nickel, which form a passive oxide layer on the surface, protecting the metal from rust and chemical attack. Grade 316 stainless steel, on the other hand, has an added molybdenum component. This makes it even more resistant to corrosion, especially in harsh conditions such as those involving exposure to seawater or highly chlorinated water. The choice of grade depends on the specific application requirements, ensuring optimal performance and longevity