BDF Buried Water Tank

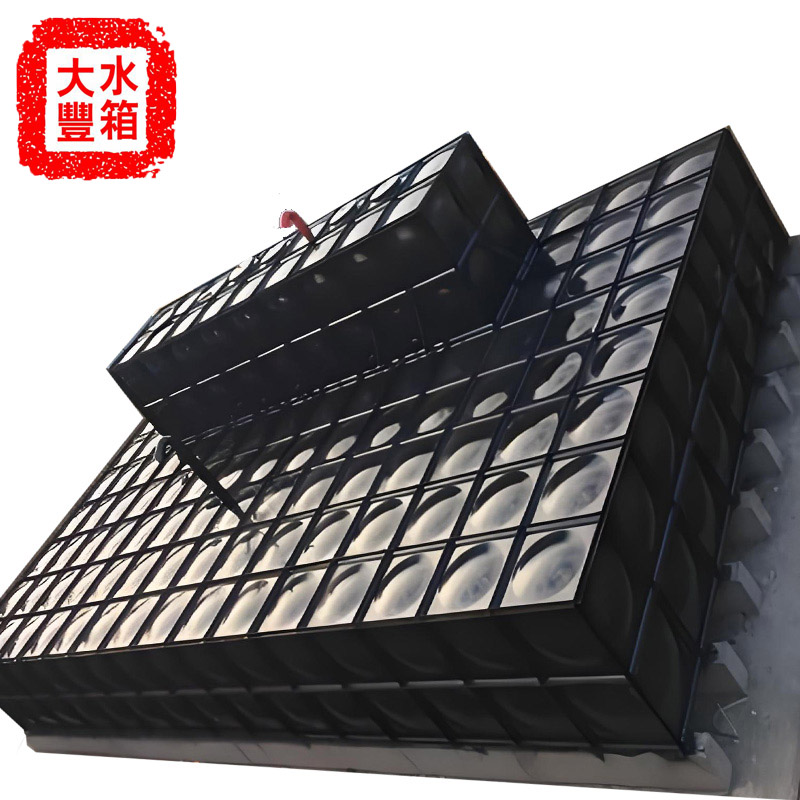

The name BDF includes the meaning of its composite sheet: B - refers to stainless steel, D - refers to galvanized sheet, and F - refers to composite. BDF water tank plate is a water tank plate formed by laminating stainless steel plate and galvanized steel plate and stamping them once. Our main business in Dafeng is square water tanks, with a variety of specifications and complete types that can be customized according to needs.

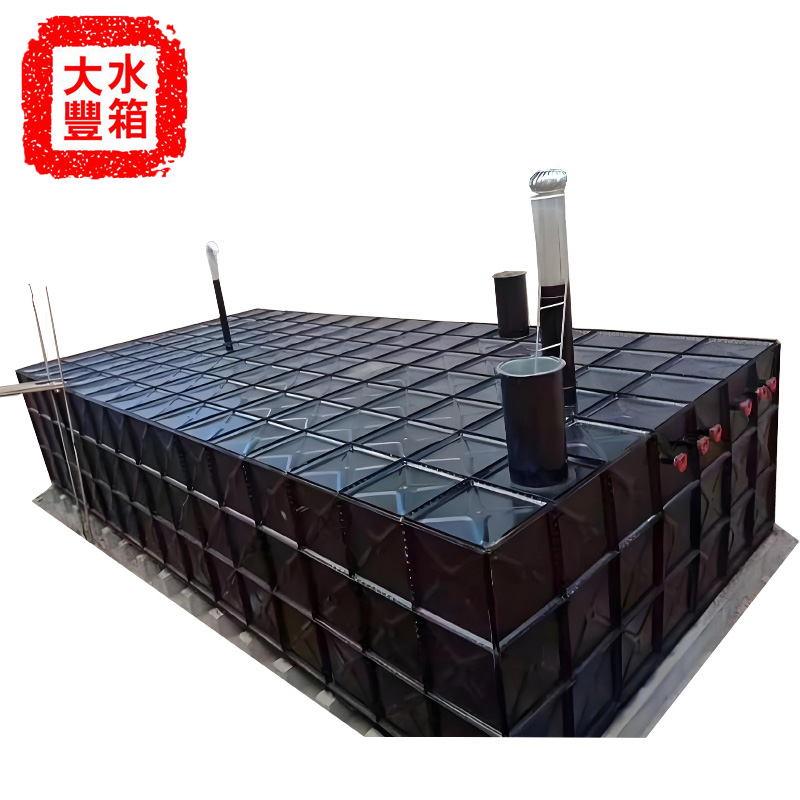

BDF underground fire water tank is a professional water storage equipment that effectively resists groundwater buoyancy through structural design and counterweight system. The core structure adopts high-strength reinforced concrete box body, combined with bottom embedded counterweight blocks and anti pull anchor rod system, forming a three-dimensional anti floating system. The side wall of the box adopts a composite structure of corrugated steel plate and concrete, which not only ensures a corrosion-resistant thickness of 8-10mm, but also converts lateral soil pressure into structural stability through concave convex pattern design. The roof adopts an arched prestressed design, with a load capacity of up to 50kN/m ², ensuring structural safety during ground vehicle compaction.

The core of BDF buried water tank can be summarized into the following five functions

Efficient water storage and space optimization

Adopting the composite stamping technology of galvanized steel plate and stainless steel to achieve underground

burial and save ground space. Modular design supports flexible assembly and adapts to different volume

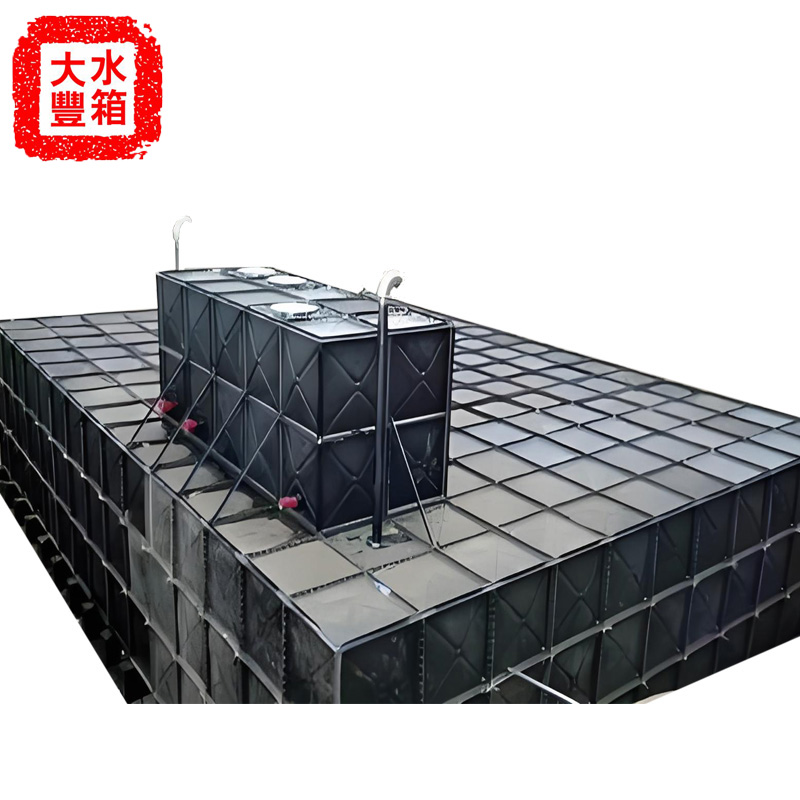

requirements.Intelligent fire linkage

Integrated water level monitoring and electric valve remote control system, supporting automatic/manual/remote

control multi-mode operation, realizing automatic start of the main pump and stable pressure in case of fire.

Equipped with pressure tanks to store initial firefighting water and solve the problem of fire extinguishing delay.

3. Structural stability guarantee

To prevent the influence of groundwater buoyancy through anti floating design (such as the self weight of the box

and the pressure of the covering soil), 90 ° angle welding or 45 ° unwelded folded edge structure is used to enhance

the pressure bearing capacity. Hot dip galvanized material ensures long-term corrosion resistance.

4. Water quality safety maintenance

Sealed design avoids surface pollution, smooth inner walls inhibit algae growth, and meets drinking water hygiene

standards. Some models are equipped with additional purification functions such as ultraviolet disinfection.

5. Energy saving operation and maintenance advantages

Compared to traditional concrete water tanks, it saves more than 30% of investment and does not require frequent

cleaning. Intelligent frequency conversion control reduces energy consumption by more than 40% and operates with

noise levels below 60 decibels.