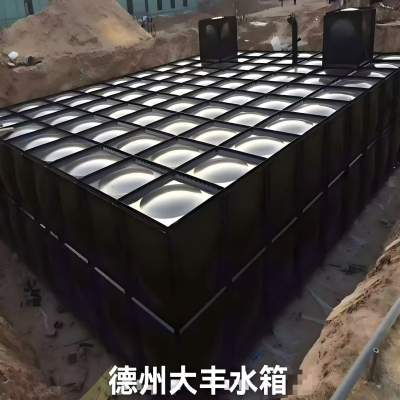

Galvanized Underground Water Tank

Corrosion Resistance

The galvanized coating on the surface of the tank offers significant protection against corrosion. It forms a barrier that shields the underlying steel from the corrosive effects of moisture, soil chemicals, and other substances present in the underground environment. This helps to maintain the structural integrity of the tank over an extended period, reducing the risk of leaks and ensuring its long-term durability.

Cost-Effectiveness

Galvanized steel is a relatively cost-effective material choice. It provides a good balance between price and performance. Compared to some other high-end or specialized materials, it offers a more affordable option without compromising too much on quality and functionality. This makes galvanized underground water tanks suitable for a wide range of applications where budget considerations are important.

Product Details of Galvanized Underground Water Tank

Material and Construction

The galvanized underground water tank is primarily constructed using galvanized steel sheets. These sheets are made of carbon steel that has been coated with a layer of zinc through a galvanization process. The zinc coating provides excellent corrosion resistance, protecting the steel from the harsh underground environment. The tank is fabricated with precision welding techniques to ensure a watertight and structurally sound enclosure. It typically consists of a bottom plate, sidewalls, and a top cover. The thickness of the steel sheets and the quality of the welding are carefully controlled to meet the required strength and durability standards.

Installation Process

The installation of a galvanized underground water tank requires careful planning and execution. First, the installation site is excavated to the appropriate depth and dimensions, taking into account the size of the tank and any additional clearance required. A proper foundation is then prepared to ensure the stability of the tank. This may involve leveling the ground, adding a layer of compacted gravel or concrete base. The tank is lowered into the excavated pit and carefully aligned. Anti-floatation measures are often implemented, such as using anchor bolts or concrete weights, to prevent the tank from being buoyed up by groundwater. Once in place, the connections for inlet and outlet pipes, as well as any necessary fittings like vents and overflow pipes, are installed and properly sealed.