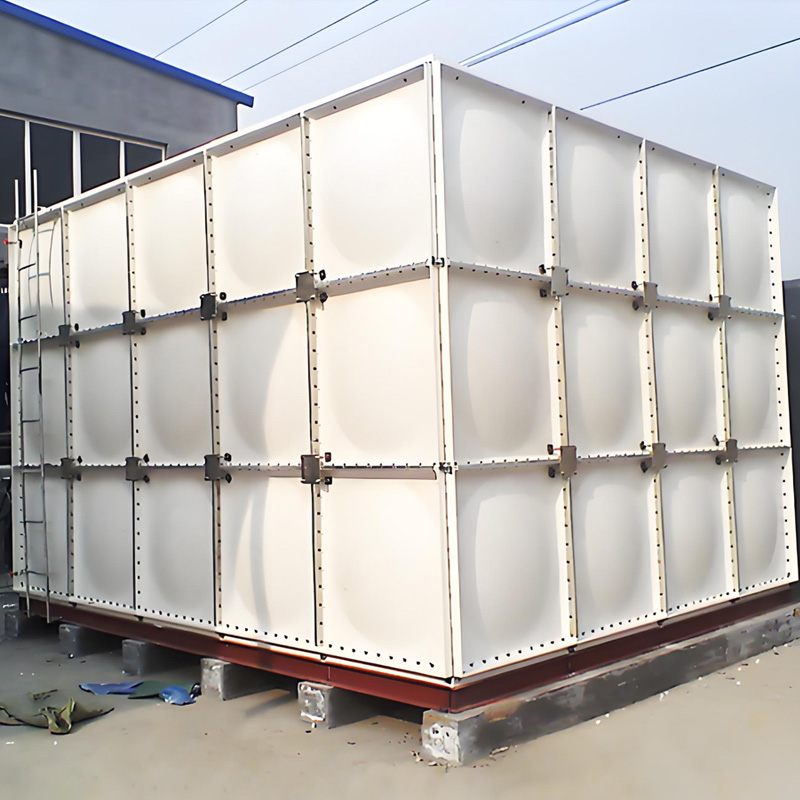

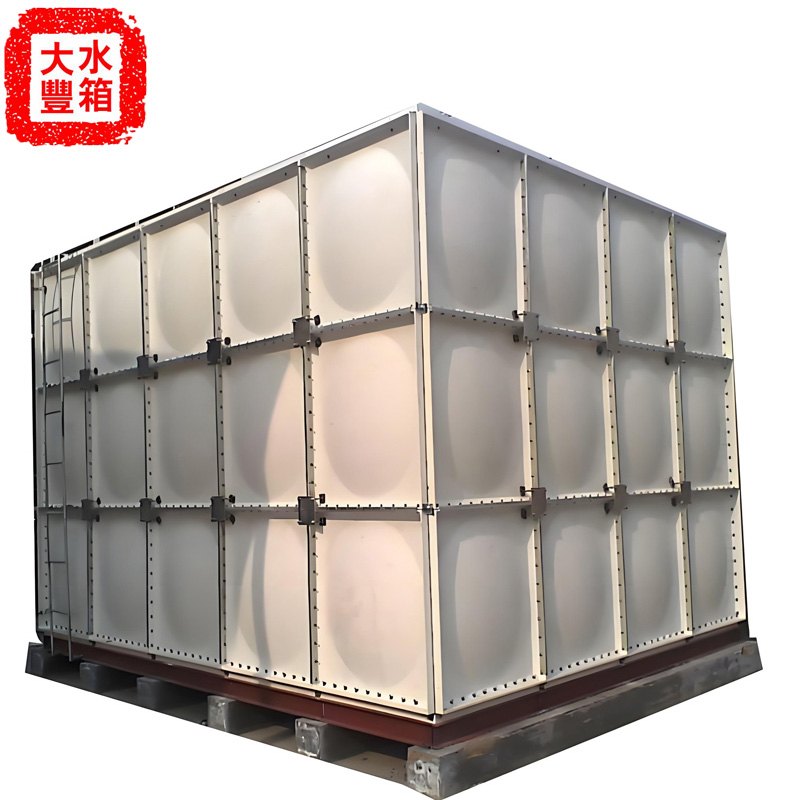

Insulated Fiberglass Water Tank

SMC insulated water tank is a new type of water tank currently used. Assembled from high-quality SMC water tank panels as a whole. Our high yield SMC insulated water tank has a beautiful appearance, corrosion resistance, light weight, long service life, compact structure, and occupies a very small area, which can better help you save land. The quality is stable and reliable, and we have accumulated decades of successful experience in technical production processes. With excellent water tank product quality, thoughtful and meticulous sales, and attentive after-sales service to customers.

Anti corrosion treatment method for the exterior of fiberglass insulated water tank:

The maintenance layer of fiberglass insulated water tanks is usually divided into two layers: metal coating and non-metal

coating. Metal coating refers to the use of corrosion-resistant metals or alloys to form a maintenance layer on the surface

of metals that are prone to corrosion and erosion. This type of coating is also called plating. There are many methods and

varieties for producing metal coatings, among which the most common is electroplating, followed by molten metal

immersion plating (hot dip plating) and chemical surface treatment. Non metallic coating refers to the use of organic

polymer materials such as paint and inorganic materials such as enamel (raw material: non-metallic minerals) to form a

maintenance layer on the surface of metal equipment or parts. This maintenance layer can completely isolate the base

metal from the environmental medium, avoiding corrosion of the base metal due to contact with stainless steel (stainless

acid resistant steel) standard parts. The external anti-corrosion treatment of fiberglass insulated water tanks refers to the

use of various methods to apply maintenance layers on the metal surface. Its function is to isolate the metal from corrosive environments, to suppress the occurrence of corrosion processes, or to reduce the contact between corrosive media and the metal surface, thereby achieving the goal of avoiding or reducing corrosion.

Insulated water tank refers to adding special industrial and insulation materials to the interlayer of the water tank, so that

the water tank can maintain a certain temperature to meet the needs of life or industry. Insulated water tanks can be

divided into stainless steel insulated water tanks, fiberglass insulated water tanks, enamel insulated water tanks, and so

on, depending on the materials used and processed.

The interior of the insulated water tank uses a type of insulation material commonly used, such as insulated cups, as the

core layer. Stainless steel water tanks are still used as the inner surface layer, while ordinary stainless steel plates are used

as the outer layer. The combination of these three materials is the most suitable and excellent combination, which has

initially formed a stainless steel insulated water tank. So the insulated water tank is composed of three layers: the core

layer, the inner layer, and the outer layer.